C/U 50~200 mm Auto

Basic Info.

| Model NO. | LL50-15LS |

| Operation | 1 Worker |

| Production Speed | 35~70m/Min, Customized |

| Web Width | 50~200 mm, Auto-Changed |

| Thickness | 0.4~0.8 mm |

| Transport Package | Main Machine Bulk and Spare Parts by Wooden Box |

| Specification | U/C light steel profiles |

| Trademark | LONGLONG |

| Origin | Tianjin China |

| HS Code | 84552210 |

| Production Capacity | 50sets/Month |

Packaging & Delivery

Package Size 590.00cm * 200.00cm * 160.00cm Package Gross Weight 5000.000kgProduct Description

C/U 50~200 mm Auto-Changed Roll Former Stud and Track Roll Forming Machine for Ceiling Drywall

Our factory has more 30 person technical team, Give us your drawings/pictures, we can customized design machines for you.

Buyer pre-purchase notices:

1. What do you mean Width & Height double automatic-adjustable?Here are two sets of automatic-adjustable system in this kind of machines.One set auto-adjustable system control Web width, the other set auto-adjustable system controls Flange height. 2.How to operate machine to achieve Width & Height double automatic-adjustable?It just reset the size (what size of new product that you want the machine produce) on PLC touch screen, the size of machine is changed automaticlly.it only need you to adjusting the feeding inlet and cutting molds,etc by manual.

Main parameters:

Regular Specifications:CW&uw50~100/ 100~200 (Width Automatic Adjutable)

| Main components list -- Whole Line | |||||

| No. | Item | Unit | Qty | ||

| 1 | Decoiler | Set | 1 | ||

| 2 | Roll rolling machine | Set | 1 | ||

| 3 | Servo tracking cutting or cut off under stop | Set | 1 | ||

| 4 | Collecting rack or Automatic packer | Set | 1 | ||

| Detailed Description | |||||

| Name | No. | Item | Parameters | ||

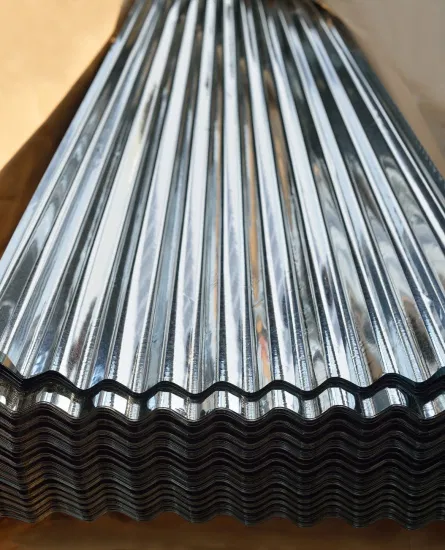

Decoiler | 1 | Roll material | Galvanized steel sheet,Cold rolled steel sheet | ||

| 2 | Roll width | Max 800mm, | |||

| 3 | Length tolerance | ±1mm | |||

| 4 | Uncoiling | Tension adjustable,unpowered | |||

| 5 | Load weight | 2Ton | |||

| Forming machine | 1 | Motor power | About 7.5KW AC | ||

| 2 | Frame structure | Overall welding structure | |||

| 3 | Forming station | About 12 stations | |||

| 4 | Dia. of shaft | ¢40~55mm | |||

| 5 | Shaft | 45#,220-250HB thermal refining | |||

| 6 | Driving method | Gear drive | |||

| 7 | Speed | 40~70 m/min | |||

| 8 | roller | Cr12, HR58-62 | |||

| Cutting device | 1 | Cutting Type | Servo tracking 45 degree Bevell cutting | ||

| 2 | Power | About 4KW, Hydraulic | |||

| Electric control | 1 | PLC | Delta | ||

| Collecting rack | 1 | Length | About 3m, asyour neeed | ||

Automatic adjustable machine:

No.1 :Light steel stud and track roll forming machines for ceiling and drywallRaw material: galvanized sheetsThickness: 0.4~0.8mmWeb Width: 50~100mm / 100~200mm Automatic Adjustable Flange Height: 28~50mm Automatic Adjustable No.2 : Ceiling U Baffle Roll Forming MachineRaw material: Aluminum/ galvanized sheetsThikcness: 0.3~0.6mmWeb width: 30 ~100mm Automatic-adjustbaleFlange height: 30~150mm Automatic-adjustbaleNo.3 : Ceiling Metal linear Roll Forming MachineRaw material: Aluminum/ galvanized sheetsThikcness: 0.3~0.6mmWeb width: 200 ~550mm Automatic-adjustbaleFlange height: can be auto-adjustbale as your need.No.4 : Heavy steel C/U steel purlin roll forming machines Raw material: galvanized sheets/Alu-zinc steel sheetsThickness: 1.8~3.0mmWeb Width: 50~160mm / 130~250mm Automatic Adjustable Flange Height: 30~65mm Automatic Adjustable

Automatic Packer These kinds of packer can packing Furring, stud and track, L steel angle, 50~300mm C/U channel.

Patent Certificate

Main Types of Exported Machine

Advantage

1.We are manufacturer and have export entitlement.2.We have more than 30 years' experience, our products have been exported to more than 80 countries all over the world.3.We supply manufacturing, design, installation, after-sales and other services.

FAQs

1.Do you have after sales support?Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.2.How to visit your company?a. Fly to Beijing airport, we can pick up you.b. Fly to Tianjin Airport, we can pick up you.3.How to get a quotation?a. Give me the profile drawing and thickness, this is the important. If no, I will suggest you some.b. Other specific requirements are welcome, such as the speed, power and voltage you want.4.You are trade company or factory?We are factory. Welcome to our workshop for visiting.5.Can you be responsible for transport?Yes, please tell me the destination port or address. We have rich experience in transport.6.How long the machine could be made?Normally speaking, common roll forming machine could be made within 45 working days.If you need machines in a hurry, we can make it for you less than a month.